Carbon Capture and Storage (CCS) for Shipping: A Revolutionary Step Towards Sustainable Maritime Transport

Carbon Capture and Storage (CCS) for Shipping

The global shipping industry plays a pivotal role in the world economy, transporting over 80% of goods traded internationally. However, this essential sector is also a significant contributor to greenhouse gas emissions, responsible for approximately 2.5% of global CO2 emissions. As the world intensifies its efforts to combat climate change, the maritime industry faces increasing pressure to reduce its environmental footprint. Among the promising solutions is Carbon Capture and Storage (CCS), a groundbreaking technology that has the potential to significantly decarbonize shipping and help meet global climate targets.

The International Maritime Organization (IMO) has set an ambitious target to neutralize the shipping industry’s carbon emissions by 2050. As the industry explores various pathways to achieve this goal, CCS stands out as a key technology that can help reduce emissions without requiring a complete overhaul of existing fleets. Let’s dive into how CCS works, its potential benefits for the shipping industry, and the challenges it faces on the road to wide-scale adoption.

What is Carbon Capture and Storage (CCS)?

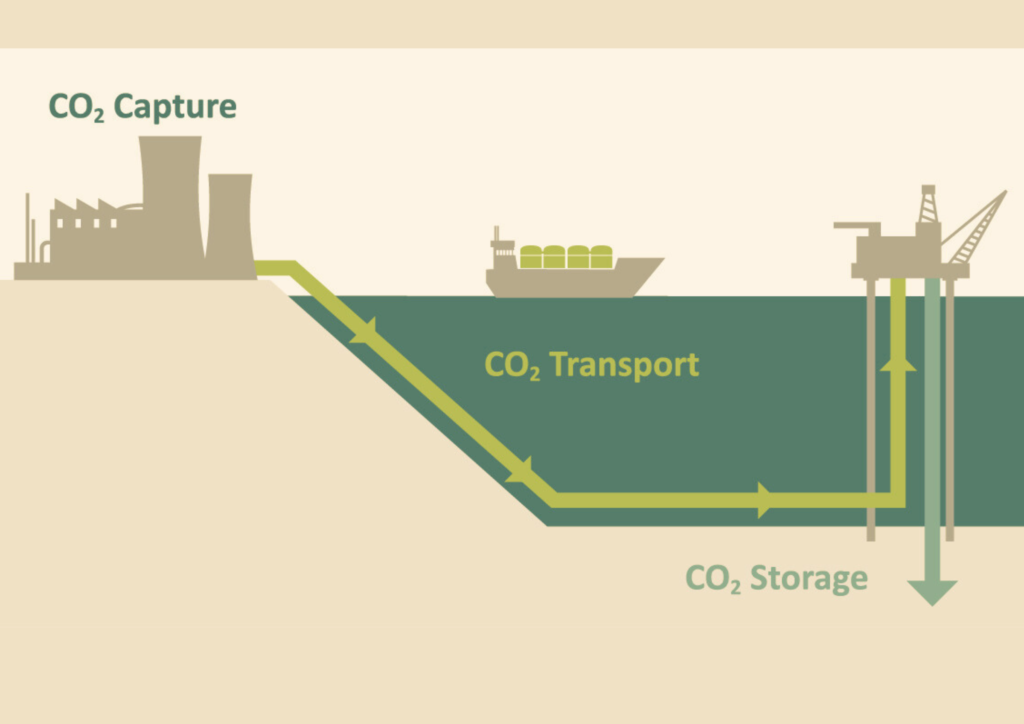

Carbon Capture and Storage (CCS) refers to a series of technologies designed to capture carbon dioxide (CO2) emissions from sources like power plants or industrial processes and store them safely, preventing the CO2 from entering the atmosphere. In the context of shipping, CCS technologies aim to capture CO2 directly from a ship’s exhaust system, compress it into a liquid form, and store it on board for later disposal or permanent storage at port.

This technology presents a unique opportunity for the maritime industry to dramatically reduce its carbon emissions, even with the current reliance on fossil fuels. By implementing CCS, shipping companies could achieve substantial reductions in emissions without needing to switch to new fuels or retrofit engines completely, making it an attractive short-to-medium-term solution for reducing the environmental impact of maritime transport.

Featured News

Plugged In but Priced Out? UK Shore Power Faces a Commercial Reality Check

Moscow vs Tehran: Discount Battle Intensifies as China Becomes the Main Prize

Panama Cancels Canal Port Concessions, Hands Temporary Control to Maersk and MSC

China’s Autonomous Feeder Nails First Fully Automated Berthing

How Does CCS Work in Shipping?

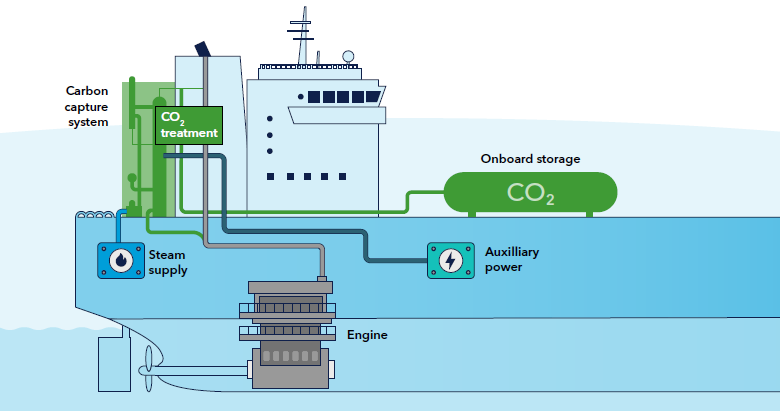

The methodology behind CCS for shipping involves three primary steps: capture, compression, and storage. Each step plays a crucial role in ensuring that CO2 is safely removed from ship emissions and stored securely for long-term environmental protection.

1. Capturing CO2 Emissions

The first step in the CCS process is capturing the CO2 from the ship’s exhaust gases. This can be done using a variety of methods, with post-combustion capture being the most widely studied and developed. In this process, the exhaust gases are passed through a scrubbing system that uses a chemical solvent—often an amine solution—to absorb the CO2 from the exhaust stream.

Another method being explored is oxy-fuel combustion, where the ship’s engines burn fuel in an oxygen-rich environment instead of air. This results in a flue gas that is mostly CO2 and water vapor, making it easier to separate the CO2 from other gases. Though promising, this method requires major modifications to existing engine systems and is not yet in widespread use.

2.Compressing and Storing CO2

Once the CO2 is captured, it needs to be compressed into a dense liquid form for safe and efficient storage. The captured CO2 is pressurized to high levels—typically between 100 to 150 bars—and cooled to maintain its liquid state. This allows the CO2 to be stored in relatively compact, high-pressure tanks on the ship.

These storage tanks must be designed to withstand the pressures and temperatures associated with liquid CO2. Engineers must also ensure that the tanks are equipped with safety mechanisms to prevent leaks or accidents during transport.

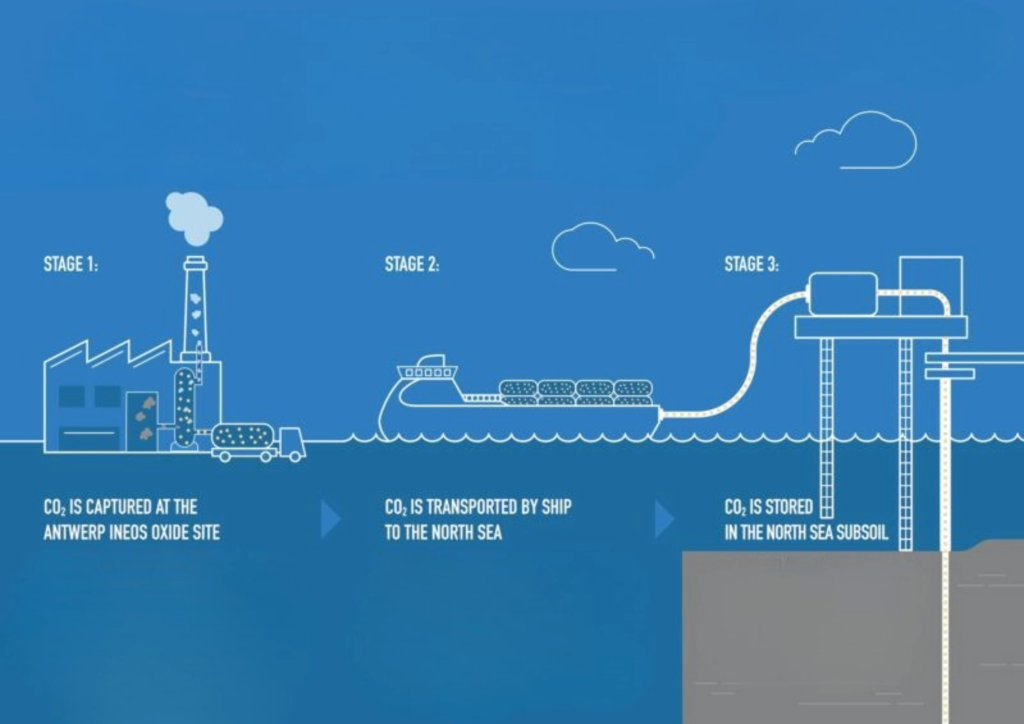

3.Offloading and Long-Term Storage

After the ship reaches its destination port, the CO2 is offloaded from the storage tanks using specialized pumps and transferred to onshore facilities. These facilities are responsible for the permanent storage of the CO2, typically by injecting it into geological formations—such as depleted oil and gas reservoirs—or into deep-sea storage sites where the CO2 is contained safely for centuries.

The development of infrastructure to handle CO2 offloading and permanent storage is one of the biggest challenges in scaling CCS for shipping. Ports need to be equipped with specialized facilities to safely handle and store captured CO2, which will require significant investment in both technology and infrastructure.

Companies Adopting CCS in Shipping

Several leading shipping companies and organizations are already exploring and deploying Carbon Capture and Storage technology to reduce their emissions. Here are some of the key players taking significant steps toward adopting CCS for shipping:

- MSC Group

The Mediterranean Shipping Company (MSC), one of the world’s largest container shipping firms, is actively involved in research and development of carbon capture technologies. MSC has partnered with Havyard Group, a Norwegian shipbuilding and marine technology company, to explore the feasibility of installing CCS systems on ships. Their focus is on developing a carbon capture system that can reduce emissions from large vessels, aiming for zero emissions in the coming decades.

- Maersk

Maersk, the world’s largest container shipping company, has made significant strides in integrating CCS technologies into its operations. Maersk is working with several technology providers to test the potential for CCS systems aboard its ships, including Carbon Clean Solutions. The goal is to capture CO2 emissions from the exhaust and store it either onboard or offloaded at port facilities. Maersk’s commitment to reducing its carbon footprint is part of its ambitious Net Zero 2050 initiative, which includes a range of decarbonization strategies such as CCS, biofuels, and renewable energy.

- Wallenius Wilhelmsen

This Norwegian-Swedish shipping company, known for its roll-on/roll-off (RoRo) services, is testing CCS technologies as part of its broader green shipping strategy. Wallenius Wilhelmsen has partnered with Norwegian company, Aker Solutions, to develop carbon capture technologies for its vessels. This partnership aims to test CCS on a series of ships, reducing CO2 emissions while still using traditional fuels. The captured CO2 will either be stored on board or transported to permanent storage facilities.

- DHL and DB Schenker

In a bid to tackle emissions from its global logistics and shipping operations, DHL and DB Schenker, two major logistics companies, have explored CCS solutions for their fleets. These companies are collaborating with engineering and energy firms to develop carbon capture solutions for their shipping operations. The adoption of CCS is part of their larger goal to achieve carbon-neutral logistics by 2050.

- Norwegian Shipowners’ Association (NSA)

In addition to individual companies, the Norwegian Shipowners’ Association (NSA) has been advocating for the adoption of CCS technology in the maritime sector. The NSA, which represents a significant portion of the world’s commercial shipping fleet, has called for the development of a global carbon capture infrastructure to support the transition to lower emissions in shipping. The association is working with both public and private sector stakeholders to accelerate the deployment of CCS technologies across Norwegian-owned vessels.

Benefits of CCS for the Shipping Industry

CCS presents several significant advantages for the shipping industry, particularly as it seeks to meet stringent emissions reduction targets. Here are a few of the key benefits:

- Immediate Emissions Reductions

One of the most compelling reasons to adopt CCS is its potential for immediate emissions reductions. Ships equipped with CCS systems can capture up to 90% of the CO2 produced by their engines, offering a substantial reduction in the environmental impact of each vessel. This technology could allow the industry to make significant progress toward decarbonization even before alternative fuels like hydrogen or ammonia become widely available.

- Flexibility and Compatibility

CCS can be applied to both newly built ships and existing vessels, making it an attractive solution for the entire fleet. Ships already in operation can be retrofitted with CCS systems, allowing for a relatively smooth transition toward greener operations. This flexibility means that CCS can be deployed quickly and on a large scale, which is critical in meeting the IMO’s 2050 emissions reduction goals.

- Complementary to Other Decarbonization Technologies

CCS can also work in tandem with other decarbonization strategies, such as low-carbon fuels or energy-efficient ship designs. As the industry explores longer-term solutions like ammonia or hydrogen-powered ships, CCS can act as a bridge technology that allows for immediate reductions in emissions while the infrastructure for these alternative fuels is being developed.

Challenges and Roadblocks to CCS Adoption

While CCS holds great promise, several challenges must be addressed before it can be adopted on a wide scale in the shipping industry:

- High Costs

The initial cost of installing CCS systems on ships is high, and retrofitting existing vessels is even more expensive. This could be a major barrier for shipping companies, particularly smaller operators. Additionally, the ongoing costs of maintaining and operating CCS systems—such as the energy required for CO2 capture—could further strain profitability.

- Infrastructure Development

For CCS to be viable at scale, ports must invest in specialized facilities for offloading and storing CO2. This infrastructure is not yet widespread, and the cost of developing it could be prohibitive. International collaboration and government incentives will be essential to drive investment in port infrastructure and ensure that CO2 can be safely stored and transported.

- Regulatory and Safety Concerns

There are also regulatory hurdles related to the safe storage and transport of CO2. Clear international guidelines and safety standards must be established to ensure that CCS systems operate effectively and do not pose risks to human health or the environment.

Conclusion: A Greener Future for Shipping

Carbon Capture and Storage (CCS) represents a transformative opportunity for the shipping industry to significantly reduce its carbon footprint and contribute to global climate goals. While the technology is still in the early stages of deployment, its potential to cut emissions by up to 90% is undeniable. As the shipping industry continues to explore new ways to decarbonize, CCS can serve as a bridge solution that allows for meaningful emissions reductions in the short term, while long-term technologies like alternative fuels take hold.

To realize this potential, the industry must overcome challenges related to cost, infrastructure, and regulation. However, with continued investment and collaboration between stakeholders, CCS could play a crucial role in charting a path toward a more sustainable and carbon-neutral future for global shipping.

As the maritime sector embraces innovation, CCS may prove to be the key to unlocking the industry’s full decarbonization potential—making the world’s oceans not just pathways for trade, but also symbols of environmental stewardship.